Technology

Stellarators are the most efficient, steady and stable fusion devices.

Several approaches are close to demonstrating net fusion electricity. Laser fusion compresses a capsule to very high pressures by means of powerful lasers. Tokamaks and stellarators are doughnut shaped devices that magnetically levitate hot ionized gases (plasmas) and heat them to temperatures hotter than the Sun.

Stellarators have a competitive advantage over Laser Fusion

-

Stellarator heating has higher off-the-plug efficiency: delivering 1kWh to the plasma costs 2-3 kWh of electricity in a stellarator, compared to over 100 kWh in laser fusion.

Another advantage is that stellarators can stay “on” all the time, whereas high power lasers are pulsed and have low repetition rates.

…and over Tokamaks…

-

Stellarators confine plasmas as well as tokamaks of the same size and magnetic field*, but are simpler to operate and energetically more efficient because they do not need a current in the plasma. As a result, stellarators get rid of the current-related instabilities that plague tokamaks, and are naturally steady rather than pulsed. They also get rid of the power-hungry current drive systems that tokamaks require to “stretch” their pulses, meaning that most stellarator electricity output goes to the grid rather than being recirculated to the power plant.

* Source: Magnetic configuration effects on the Wendelstein 7-X stellarator by Nature Physics

…there are challenges

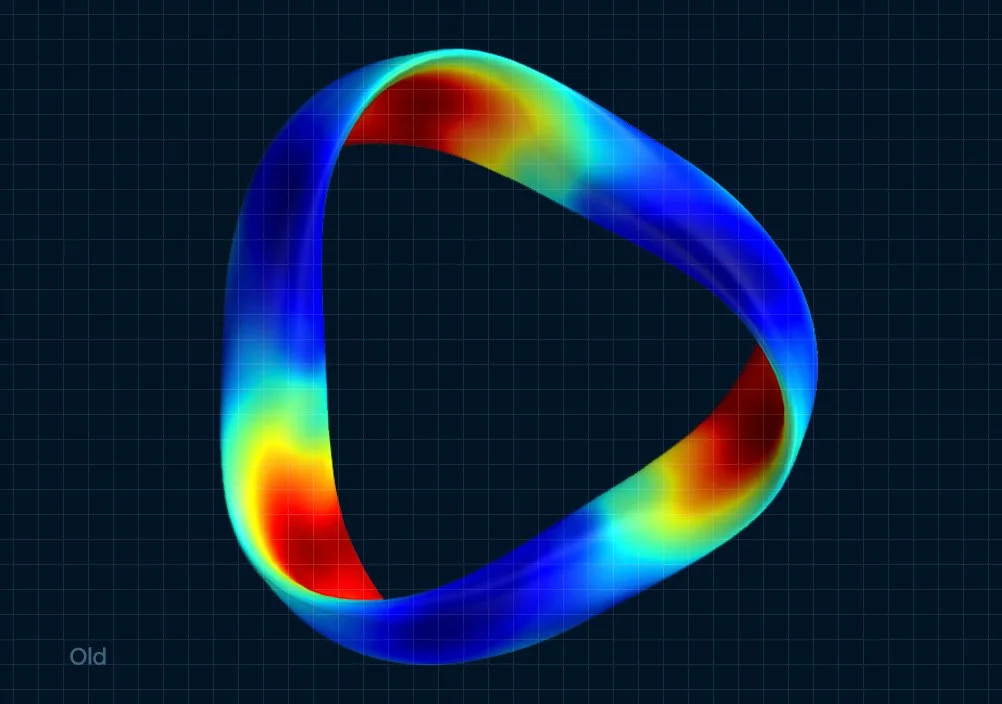

Instead of relying on plasma currents like tokamaks, stellarators confine the plasma by specially shaped 3D magnetic fields. Historically this translated in complicated coils of expensive and time-consuming design, modelling and manufacturing.

But not anymore, thanks to our unique technologies! Our simplifications have clear competitive advantages in the race to the first power-plant.

Renaissance Fusion’s simplified stellarators

Simple coil surfaces

We are proving that simple, elegant coils can generate complex magnetic fields. In other words, we decouple engineering from physics: we build 1D or 2D coils (typically on cylindrical surfaces, not necessarily of circular cross-section) to generate the 3D magnetic fields needed in stellarators and several spin-offs.

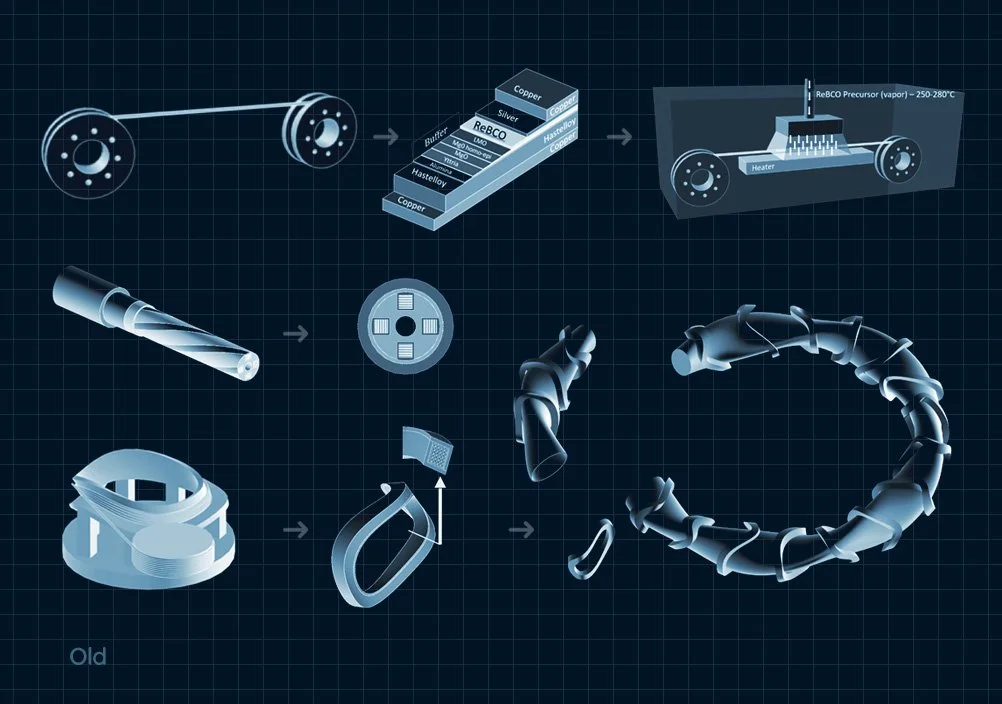

Simple HTS Manufacturing

Only High Temperature Superconductors (HTS) can generate the high magnetic fields needed to make fusion smaller and cheaper. The benefits are impressive: a 4x increase in magnetic field reduces the plasma volume by 256x.

The problem is that these man-made materials are scarce and expensive, but at Renaissance Fusion we are skipping some intermediate steps (tapes, cables) and directly depositing and patterning HTS on large surfaces. It’s like changing paradigm from individual transistors to photolithography. We think it will be a big revolution.

Thick, flowing liquid walls

Our liquid Lithium-based walls stop 99.99% of the neutron energy before they can reach solid materials and make them radioactive. Brute force would require a 1.5 meter thick liquid wall. With clever materials, we do it in 40 cm.

The liquid metal is also the “working fluid” extracting heat from the stellarator and transferring it to turbine-propelling steam. Plus, it copes with the high temperatures and heat-fluxes of compact fusion.

Thirdly, it breeds one of the fuels: Tritium. Our liquid materials allow Li tritide extraction by simple precipitation.

-

Most fusion reactions produce neutrons, making the fusion devices - not just stellarators - radioactive and difficult to maintain. Moreover, some components deteriorate quickly, increasing replacement costs.

We are the only magnetic fusion entity, public or private, that surrounds the plasma with a liquid wall thick enough to stop most neutrons. Surrounding the plasma is necessary because neutrons are emitted in all directions.

We obtain this by circulating a small electric current (dashed line) in the liquid metal (blue), via electrodes (+,-). The current interacts with the strong magnetic field B that confines the plasma. As a result, the liquid metal injected from the top of a cylinder does not fall vertically, but along its solid walls, and shields them.

Lithium is a good neutron absorber, but thickness is reduced by adding good attenuators like Lithium hydrides. As a bonus, hydrides facilitate the precipitation of Lithium tritide, from which Tritium is extracted.

Want to learn more? Check out this video in which Francesco Volpe talks about our technology.